Case Study: GE Digital

$42M Pipeline. 6 Patents. 4 Weeks.

Industrial IoT | Predictive Analytics | Oil & Gas

A dead product with zero market traction. 4 weeks to a major conference.

One uncomfortable question changed everything.

The 5-Year Challenge

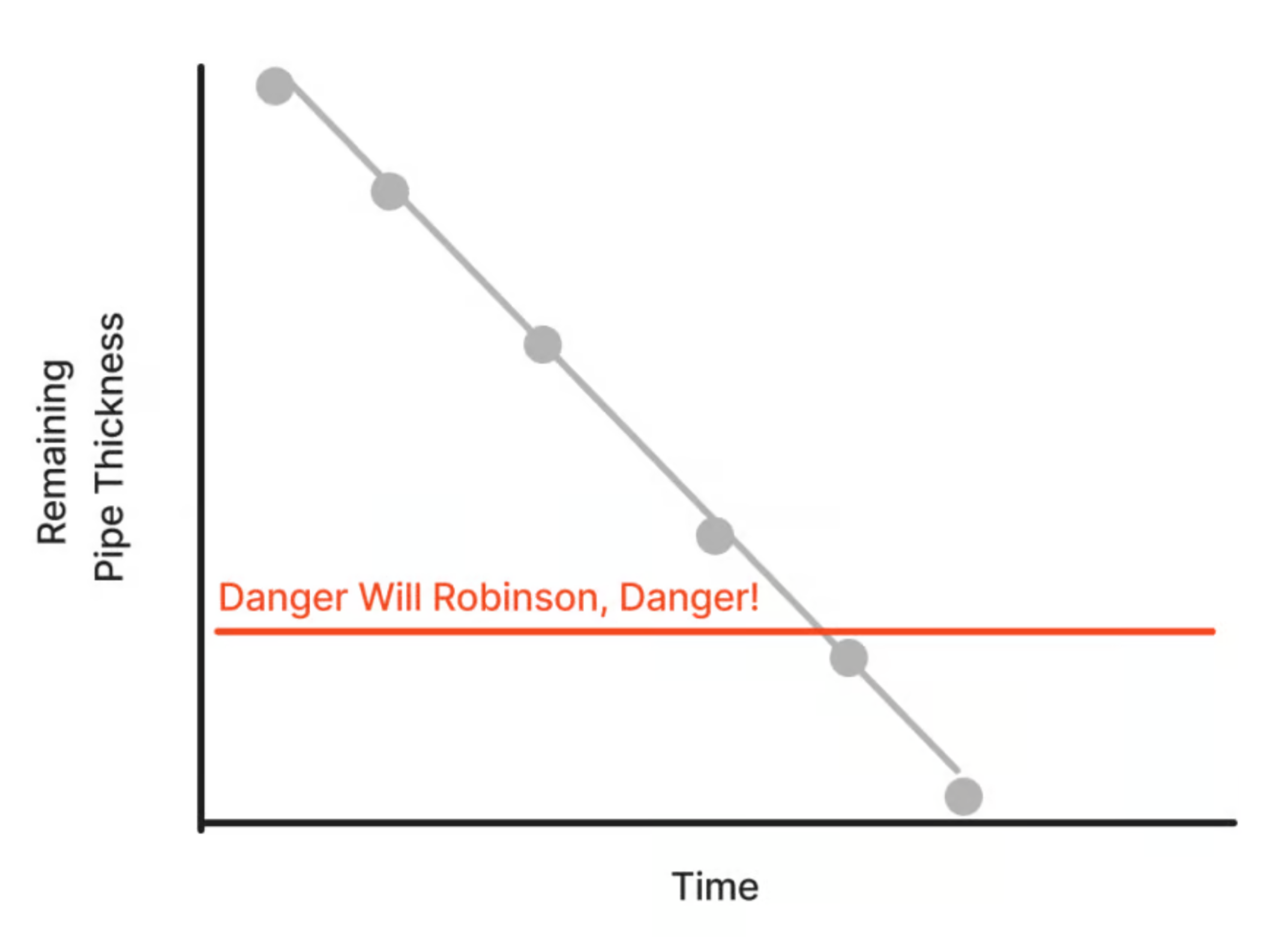

The company had spent 5 years building cheap sensors to measure pipe wall thickness — a massive market opportunity. Pipes make up 40% of factory investment and wear out in 5-10 years.

The problem: The sensors weren't accurate enough. 5 years of R&D trying to match expensive manual equipment with cheap IoT sensors. No product-market fit. No path forward.

Leadership wanted a "Wow" demo for a major industry conference. As a Sr. Director, Head of AI Experience Strategy, I had 4 weeks to deliver what 5 years couldn't.

I pulled together 12 product managers, data scientists, and Oil & Gas SMEs across 7 time zones. Using the Snowball Sprint Framework, we delivered a pivot 5 years in the making — in 4 weeks.

The Pivot

What They Were Building

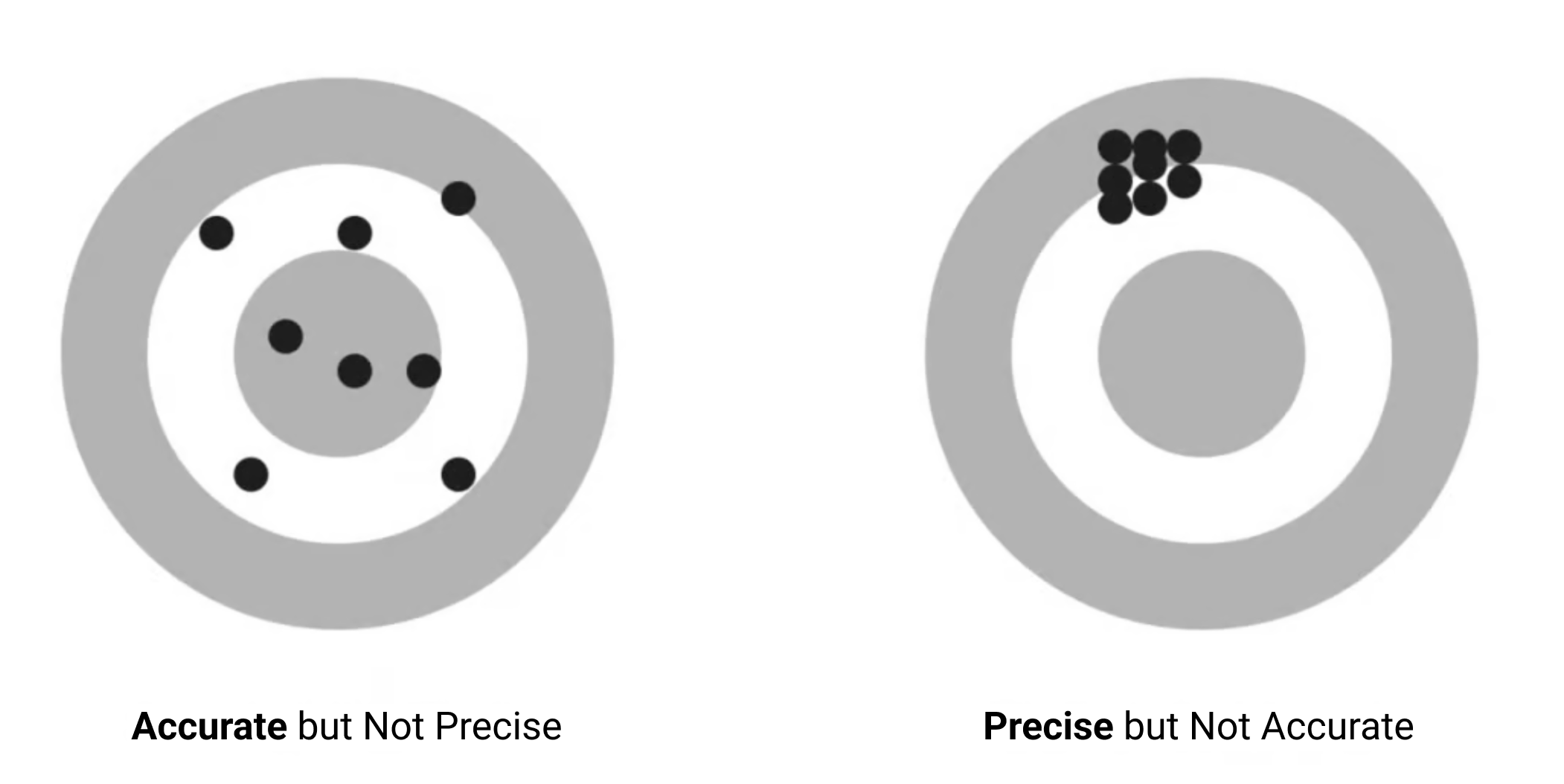

5 years chasing accuracy. The assumption: cheap sensors had to be as accurate as expensive manual equipment.

Wrong assumption.

Government inspections already mandated accurate manual readings. Customers didn't need another way to measure thickness — they needed to know how fast their pipes were corroding and what to do about it.

What Customers Actually Needed

Customers cared about precision (rate of change), not accuracy (absolute thickness). They wanted to know: How fast is this pipe corroding? What can I do to extend its life?

The cheap sensors were already precise. They just weren't accurate. And precision was what mattered.

The Lucky Twist

The company was also the leading supplier of internal pipe coatings designed to stop corrosion. The customers were already buying the solution — they just needed AI to tell them where and when to apply it.

The Snowball Sprint

The Uncomfortable Question:

"Just what the heck is the AI supposed to predict here? The corrosion graph is a simple linear equation."

-

I facilitated intensive brainstorming sessions reviewing the reality (inaccurate sensors after 5 years of R&D), and what could be done to create ROI for key use cases, customers actually cared about.

-

The breakthrough came when I asked the uncomfortable question:

“Just what the heck is the AI supposed to predict here? The corrosion graph is a simple linear equation."

That question exposed the real insight: government inspections already mandated accurate manual readings. Customers didn't need another way to measure thickness. They needed AI to recommend ways to extend the life of their pipes.

-

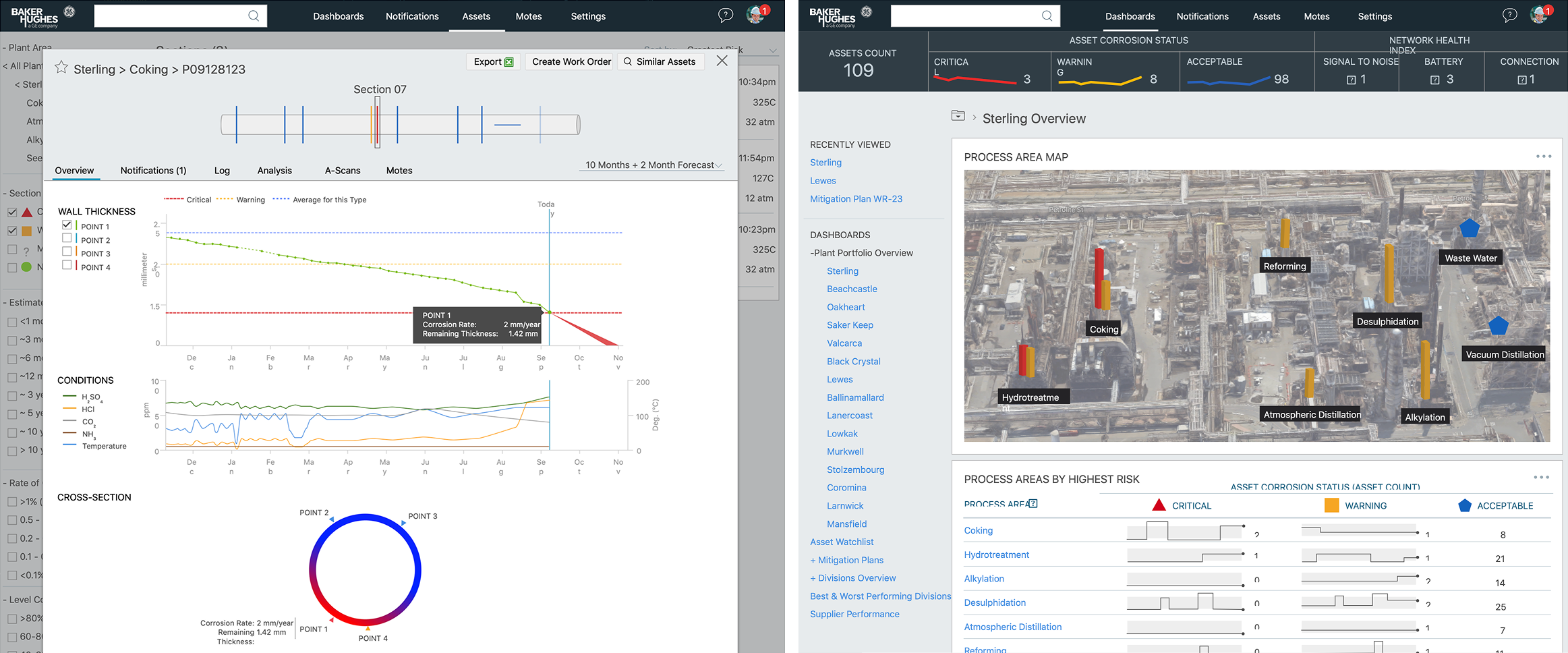

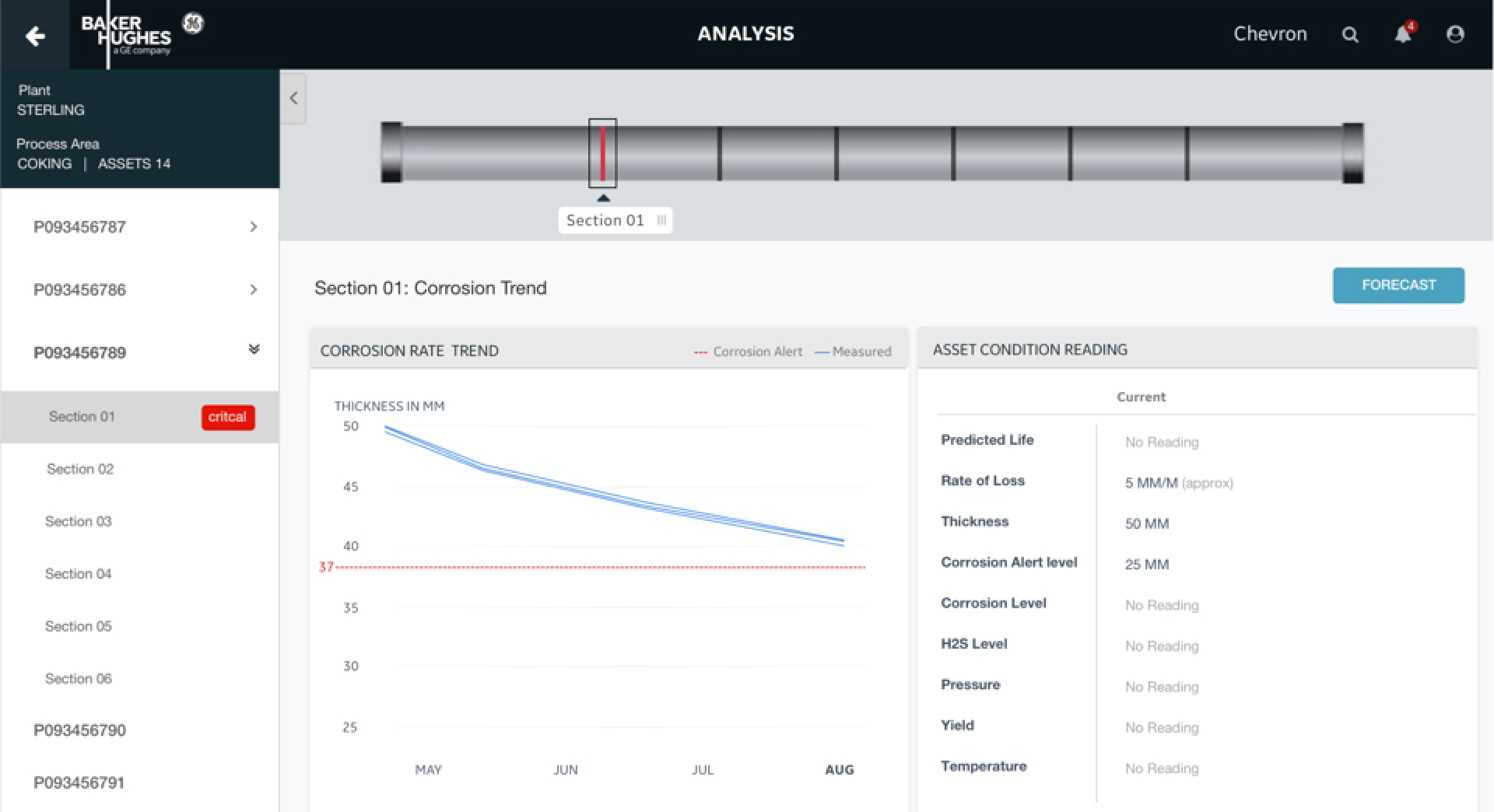

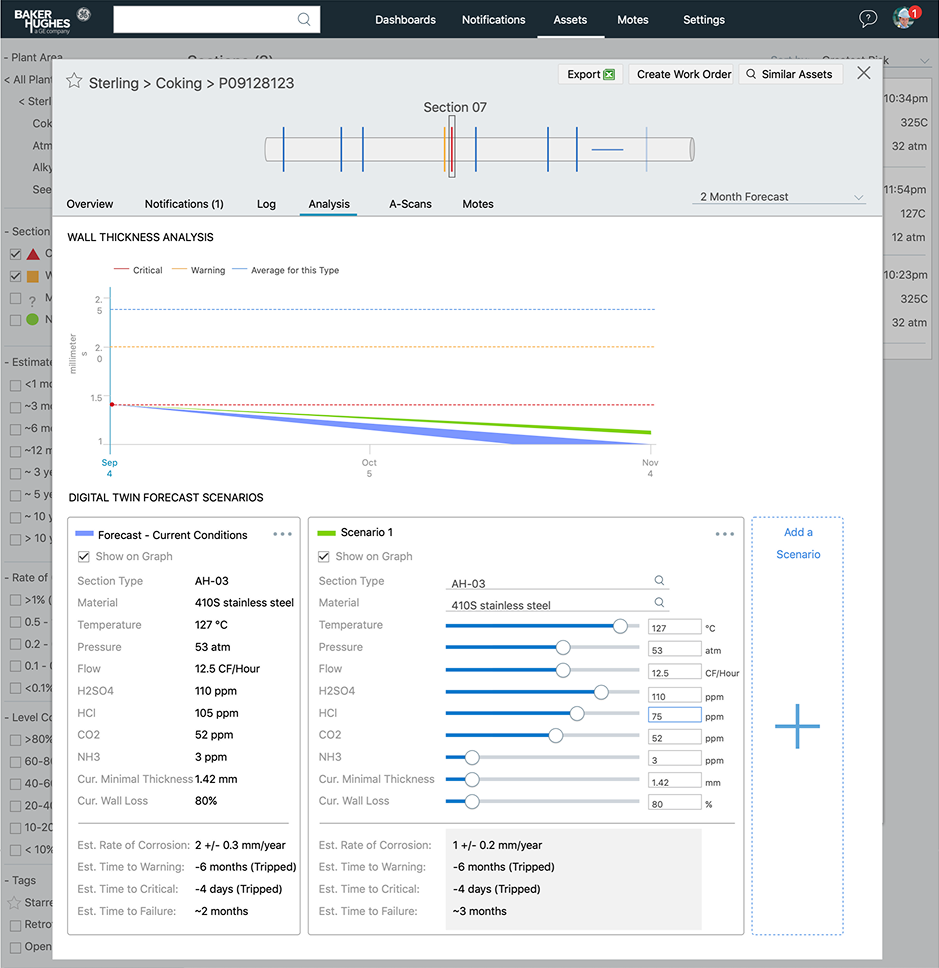

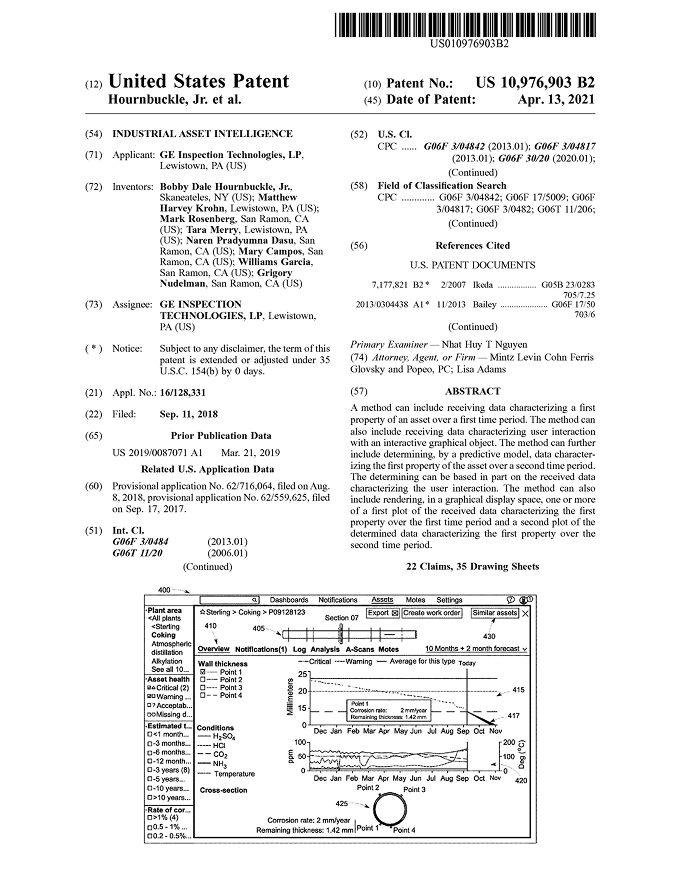

Rapid prototyping with the cross-functional team. Asset 360 views consolidating disparate data sources. Predictive analytics showing estimated time to failure. Scenario comparison showing how different coatings would extend pipe life.

-

High-fidelity demo completed. Design system extending GE Predix. Ready for the conference floor.

At the conference, something unexpected happened.

Customers didn't just watch the demo. They didn't just ask questions. They pulled out checkbooks.

"When can I buy this?"

Over and over.

A product that had zero traction for years generated $42M in pipeline from a single conference — the highest pre-sales of any GE Digital product.

The "When Can I Buy This?" Moment

Validated Impact

4 Weeks

Dead product to conference demo

$42M

Pipeline from single event

6 Patents

Filed on novel UX for AI patterns

1st

Highest pre-sales in GE Digital history

6 Patented Insights. A Foundation for the Future.

The Vision Prototype didn't just sell — it created defensible IP.

The scenario comparison UI

The predictive coating recommendations

The Asset 360 pattern

The Predictive Pipe Failure Search, Analysis, and Dashboards

All novel. All patentable.

6 patents filed on predictive analytics and AI/IoT interaction models. The designs became the foundation for multiple new product lines.

The Vision Prototype I designed in 2017 became Baker Hughes' Predictive Corrosion Management (PCM) platform — now a Market Leader deployed globally through a strategic partnership with SGS.

Same AI experience. Same scenario comparison. Same digital twin approach. Now in production globally.

"PCM is one of our core offerings to help customers make the invisible, visible... a predictive digital solution that is becoming a benchmark for corrosion monitoring across several industries. This agreement will play a key role in improving safety, reducing equipment downtime, and improving operations for our customers globally."

— Holger Laubenthal, CEO of Inspection Technologies, BHGE

7 Years Later - The Long-Term Impact

What Leaders Say

"Greg worked with me at BHGE to build the UX/UI of my product. Greg's ability in understanding the context, drive the description of the personas and identify the key interactions was amazing. What I appreciated the most was his ability to lead a group of more than 10 people, listening to the inputs of each and everyone of them and then brilliantly synthesize everything in an effective UX/UI.”

— Fabio Mazzocchetti

CTO AI in Energy (former BHGE)

"Greg was a keystone in helping us figure out how to take very complex, high-volume data, and present this in a way which was both meaningful and familiar…Greg’s sense for user needs and UX flow is world class, for many diverse applications!”

— Matt Stone

Founder, VP of Product (former BHGE)

"Verdantix 2024 Green Quadrant: Baker Hughes emerged as a market leader for APM software... due to its strong condition monitoring, predictive maintenance and maintenance strategy optimization capabilities."

— Verdantix

"Greg is an extremely passionate professional, with great UX-UI background. I had the pleasure to work with him at BHGE and I mostly appreciated the speed and effectiveness of his idea generation process. Designing use cases with Greg was an amazing and re-assuring experience for his capability to listen, execute and get results.

— Alessandro Bettini

AI Senior Solution Manager (former BHGE)

The Bottom Line

5 Years of Struggle (What I fixed)

Time to validate: 5 Years

Customer value: Compete with Manual Inspections

Outcome: Multi-million R&D Spend on Wrong Use Case

IP: None

Snowball Sprint (What I did)

Time to validate: 4 Weeks

Customer value: Enable Proactive Maintenance

Outcome: $42M Pipeline from 1 Event, Flagship PCM Product

IP: 6 Patents

Constraints aren't blockers. They're fuel.

The company spent 5 years solving the wrong problem because they never asked:

"What would make this valuable?"

The sensors they'd built were already good enough.

They just needed a 4-week Snowball Sprint to discover $42M in value and lay the foundation for a flagship product customers actually wanted to buy.

Let’s Talk

GE Digital went from zero traction to $42M pipeline in 4 weeks — not by building better sensors, but by asking better questions.

In 30 minutes, we'll talk through your AI challenges and see whether a Snowball Sprint can reframe your problem.

No pitch — just an honest conversation.